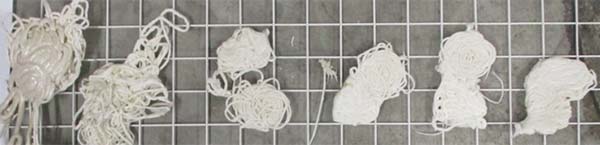

Examples of Z CLEAN™ S81G in use.

Condition

- Molding machine type

- Injection molding machine (80t)

- Preceding resin

- PEEK / GF30% Sliver

- Succeeding resin

- PC

- Temperature conditions

- C1:698 C2:698 C3:698 N:698(℉)

C1:370 C2:370 C3:370 N:370(℃) - Molding machine conditions

- Screw rotation 50%

- Injection conditions

- Back pressure conditions 0mPa

- Test materials

- ① S81G New development product

② S80G Conventional product

③ Competitor's product

Result of purging

① S81G

PURGING PROCESS

PEEK⇒S81G

| CLEANING CONDITION | The developed product has stable lump during purging and has good performance without any problems with workability. |

|---|---|

| AMOUNT OF PURGING AGENT | 400g |

② S80G

PURGING PROCESS

PEEK⇒S80G

| CLEANING CONDITION | The conventional products are difficult to handle because the lump are unstable during purging. |

|---|---|

| AMOUNT OF PURGING AGENT | 500g |

③ Competitor's product

PURGING PROCESS

PEEK⇒Competitor's product

| CLEANING CONDITION | When using competitor's product, discoloration occurs after replacing with PC. |

|---|---|

| AMOUNT OF PURGING AGENT | 800g |

Result

The developed purging agent S81G uses less resin than the conventional S80G, making it useful for color changing and translating from PEEK resin at 698℉(370℃).